wheat milling flow chart

3 Flow chart of the wheat dry milling process. - ResearchGate

2023年10月13日 The most common cereal processes include dry milling (wheat and... Edible Grain, Cereal and Corn ResearchGate, the professional network for scientists.

Read More

(PDF) 1 - Introduction to cereal processing and by

2018年2月14日 The most common cereal processes include dry milling (wheat and rye), pearling (rice, oat, and barley), wet milling (corn and

Read More

Introduction to cereal processing and by-products

2018年1月1日 Flow chart of the wheat dry milling process. First, break rollers break the wheat kernel and remove the endosperm and germ from the pericarp. The break material

Read More

Chapter 7 Roller Milling of Wheat - ScienceDirect

2007年1月1日 Key issues in milling of wheat. Milling wheat into flour for human consumption is a mature industry that operates on highly efficient processes at low

Read More

Milling of Wheat – Understanding Ingredients for the

4 Milling of Wheat Milling of wheat is the process that turns whole grains into flours. The overall aims of the miller are to produce: A consistent product; A range of flours suitable

Read More

Flow chart of the wheat processing operations.

2 天之前 Process analysis method of energy was adopted to evaluate the energy requirement for each of the operations involved in the processing... Wheat, Flour and Milling ResearchGate, the ...

Read More

3: Milling of wheat - Springer

2017年8月26日 Any type of mill may be used for this purpose. In most cases it will be a hammer mill, which in one processing step fragments the grains and pulverizes them by

Read More

Wheat Milling and Flour Testing SpringerLink

2015年1月1日 The physical structure of the wheat berry is described. The evaluation of wheat quality as it arrives at the flour mill is detailed. The cleaning and preparation of

Read More

Wheat Milling Grain Processing Bühler Group

Our CombiMill integrates our PesaMill into a flexible flour milling concept with roller mills. It is the first industrial process to produce whole wheat flour for traditional flat bread, dark

Read More

Assessing and Managing Wheat-Flour Quality Before, During and After Milling

2017年1月1日 rheology wheat products analysis wholemeal flour wheat intolerance FODMAP HACCP 22.1. Introduction For almost all purposes, wheat is milled before

Read More

Food Science and Processing: Milling of Wheat - e-Krishi

Milling of Wheat. The milling of Wheat consists in the separation of bran and germ from the endosperm and reduction of endosperm to fine flour.. Various steps are involved in making the wheat flour. These steps are shown in Figure. The traditional procedure for milling wheat in India has been stone grinding to obtain whole wheat flour.. In modern milling, the

Read More

Milling of Wheat – Understanding Ingredients for the

Milling of wheat is the process that turns whole grains into flours. The overall aims of the miller are to produce: A consistent product. A range of flours suitable for a variety of functions. Flours with predictable performance. The very first mill operation is analyzing the grain, which determines criteria such as the. gluten.

Read More

Wheat Farming, Milling Quality Requirements

2022年3月31日 •Wheat is conditioned for milling. Moisture is added in certain amounts to toughen the bran and mellow the inner endosperm. This help the parts of the kernel to be separated easily and cleanly •Tempered wheat is stored in bins from 8-24 hours, depending on the type of wheat - soft, medium or hard

Read More

3: Milling of wheat - Springer

2017年8月26日 To illustrate the milling steps in some more detail, the simple flow diagram of the experimental laboratory mill in Figure 3.4 will be discussed here. Conditioned wheat is fed to a pair of corrugated chilled-iron rollers known as the first break-rollers, one of which revolves at two-and-a-half times the speed of the other.

Read More

What’s the process of milling wheat: Step-by-step guide

2023年9月5日 Get your wheat grain berries and fill up your coffee grinder to the halfway point. Set your coffee grinder to grind for around 30 seconds. Grind for the 30 seconds. Always double-check the flour. If it is not fine enough or too fine, adjust until you’re satisfied with the consistency.

Read More

Model Project on Wheat Milling - wbfpih.gov

The process flow chart for wheat milling is as follows; VI. PROJECT COMPONENTS • Land and Building A plot of land of around 0.5 acre shall be required which would cost around Rs.2.5 lakhs. In addition to the land an average Rs. 5.0 Lakhs are required for the development of land depending on the topography of land. The cost of

Read More

Assessing and Managing Wheat-Flour Quality Before, During and After Milling

2017年1月1日 Quality assessment commences at wheat intake and continues during and after milling using a range of chemical, physical, rheological and small scale end-product tests. Different methods of quality assessment are used depending on flour specifications and local preference, but there is a commonality of information produced.

Read More

Flow chart of the wheat processing operations. - ResearchGate

2 天之前 An energy analysis conducted on a milling plant concluded that the most energy intensive operation is the milling unit with energy intensity of about 0.073MJ/kg (72.20%) of the total energy ...

Read More

Wheat Milling - Aligarh Muslim University

2020年3月29日 Wheat Milling • Wheat is a main food grain of many countries. it is one of the most important cereal and used as staple food in the form of flour. • In India a large proportion of wheat is used as atta (whole wheat flour) and maida (white flour). • The heard wheat are also ground into suji (semolina). Whole wheat is ground into atta

Read More

PMG Engineering PMG Engineering

Design of New Food Factories. We take care of all aspects of factory design in one place, including Process, Building and Civil, Utilities, Electrical and Automation, Quality Assurance, and others. Our design meets global standards on food safety and hygienic engineering. We can build new factories from ground to the best standards.

Read More

Principles of Diagram Design for Wheat Flour Mill

2020年8月8日 Chapter 1 : Wheat specification Target of milling : producing flour from wheat Row material : cleaned and conditioned wheat Physical specifications of wheat : Density: 0.75 – 0.8 ton/cubic m Hectoliter: 74 – 78 optimums 1000 kernels weight: 33 – 40 gr Wheat kernel’s size as an average is shown in fig.1 (Fig. 1: wheat size)

Read More

WHEAT-MILLING TECHNOLOGY AND WHEAT

2019年1月24日 WHEAT-MILLING TECHNOLOGY AND WHEAT PROCESSED PRODUCTS. Jan. 24, 2019 • 15 likes • 8,747 views. Download Now. Download to read offline. Science. ANCIENT MILLING

Read More

Wheat Middlings - Research and Extension Kansas

2018年6月3日 93.2 Wheat Flour consists principally of wheat flour together with fine particles of wheat bran, wheat germ, and the offal from the “tail of the mill.” This product must be obtained in the usual process of commercial milling and must not contain more than 1.5% crude fiber. (Adopted 1949.) IFN 4-05-199 Wheat flour less than 1.5% fiber.

Read More

Hazard control plan of CCP for the process of wheat milling.

Download scientific diagram Hazard control plan of CCP for the process of wheat milling. from publication: Application of Food Safety Management System (ISO 22000) In Processing of Wheat Flour ...

Read More

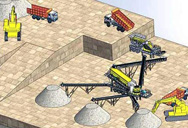

Flour milling processing technology and equipments

2023年4月7日 Its general technology flowchart should be as follows: crude wheat storage by silos, wheat pre-cleaning section, wheat cleaning section, wheat milling section, flour packing section and wheat flour storage section. Final products of wheat flour milling line will be 65%~80% wheat flour, 20%~22% wheat bran. Design for procustion capacity

Read More

Crop Process Engineering: Lesson 4. Processing of Farm

4.1 Processing of cereals Among major cereal crops processing of rice, wheat and maize, a detailed discussion is being given below: 4.1.1 Processing of Rice Paddy (Oryza sativa L.) is most important food grains of the world and nearly 2/3of population has partially or totally adopted rice as their main food.India is the world’s second largest producer of rice.

Read More

WHEAT FLOUR - NIFTEM

2021年3月8日 Wheat grains, or kernels, consist of about 85 percent of the starchy endosperm, or food-storage portion; about 13 percent of several outer layers that make up the bran; and about 2 percent of the oily germ, or embryo plant. The aim of the milling process in the manufacture of refined flour is to distinguish the

Read More

The milling process - UK Flour Millers

The flour milling process has evolved from wheat being ground between two large stone wheels (although this process does still occur in a few mills). In a roller mill the practice centres around separating the three components of a wheat seed – the white endosperm, the outer bran layers and the wheat germ.

Read More

wheat-milling-process - Udawat

2020年8月1日 Wheat Milling Process ‘Kernel’ is the wheat seed that is grown from the wheat plant. Most of the wheat plants grow up to two to four feet. The wheat head is harvested to produce food and each plant can yield 50-75 kernels. These kernels are small, dry, and suitable for storage and transportation. Then, they are milled into floor, and this ...

Read More

a resource on the production of wheat and the science

2022年6月10日 Part 1 – WHEAT PRODUCTION ... HRW wheat has good characteristics for milling and baking. The ma-jority of HRW wheat is produced in the Great Plains states between the Mississippi River and Rocky Mountains as well as significant amounts in California. HRW wheat has a significant amount of pro-

Read More

- التصنيع باستخدام الحاسب الآلي النقش وآلة طحن زد

- مطحنة الكرة مع الكرات المطاطية

- معرض محاذاة حزام سير الفحم

- جمع مطحنة بن بن

- استفاده طلا تجهیزات پردازش سنگ معدن برای فروش

- لیست طلا تجهیزات معدن و ماشین آلات

- بالطبع الفك سعر محطم

- شاكر الذهب طاولة الاهتزاز

- الفاترة طحن مطحنة قدرة

- 150tph حجر سحق وحدة بيع في الهند

- طراحی پایه وزن دستگاه های سنگ شکن سنگ معدن

- كسارات البحص في المدينة المنورة

- سنگ شکن شن کمربند

- ماشین آلات حفاری عمودی تولید کنندگان هند

- طاحونة السعر في حيدر أباد أفضل العلامات التجارية